Turcite scraping

Re-scraping of machine ways

IMS Inc. has the technical skills necessary for scraping and flaking to rebuild CNC machines regardless of the size and type.

With the use of our precision equipment, applied methods and years of experience, we can remanufacture your machine to perform at a new machine tolerance, and we are able to do it at a fraction of the cost.

Why re-scrape machine ways

The scraping procedure spreads the points of bearing contact evenly across the ways while achieving geometric alignment, flatness, parallelism, and squareness. High and low points provide oil reservoirs very important for accuracy, repeatability, and longevity.

When machine ways are not scraping in flat to each other and fitted properly, dirt and chips work their way in and scoring of the way appears. All machines are made of cast iron because of its characteristics cast iron will always remain and hold tolerance, through extreme cold or hot temperatures.

Way rails

We also evaluated way rails to ensure the rebuild is done correctly. Potential scoring and wear points are signs for regrinding.

The two types of material we scrape and flake are Cast Iron and Turcite.

Turcite® B is the traditional bearing material used on machine tool ways, transfer lines or any linear movement application in which reduced friction and wear resistance are critical design considerations. Turcite® B Slydway increases accuracy, reduces damage caused by mechanical breakdowns and lubrication failures, extends the useful life of mechanical components, saves energy and improves stick-slip performance.

Every customer and their needs are unique, give us a call so we can work together to come up with a solution that will restore the accuracy of your machine with a timeline that will work for your schedule.

Contact us today to learn more about our Turcite scraping services.

Old Turcite

New Turcite

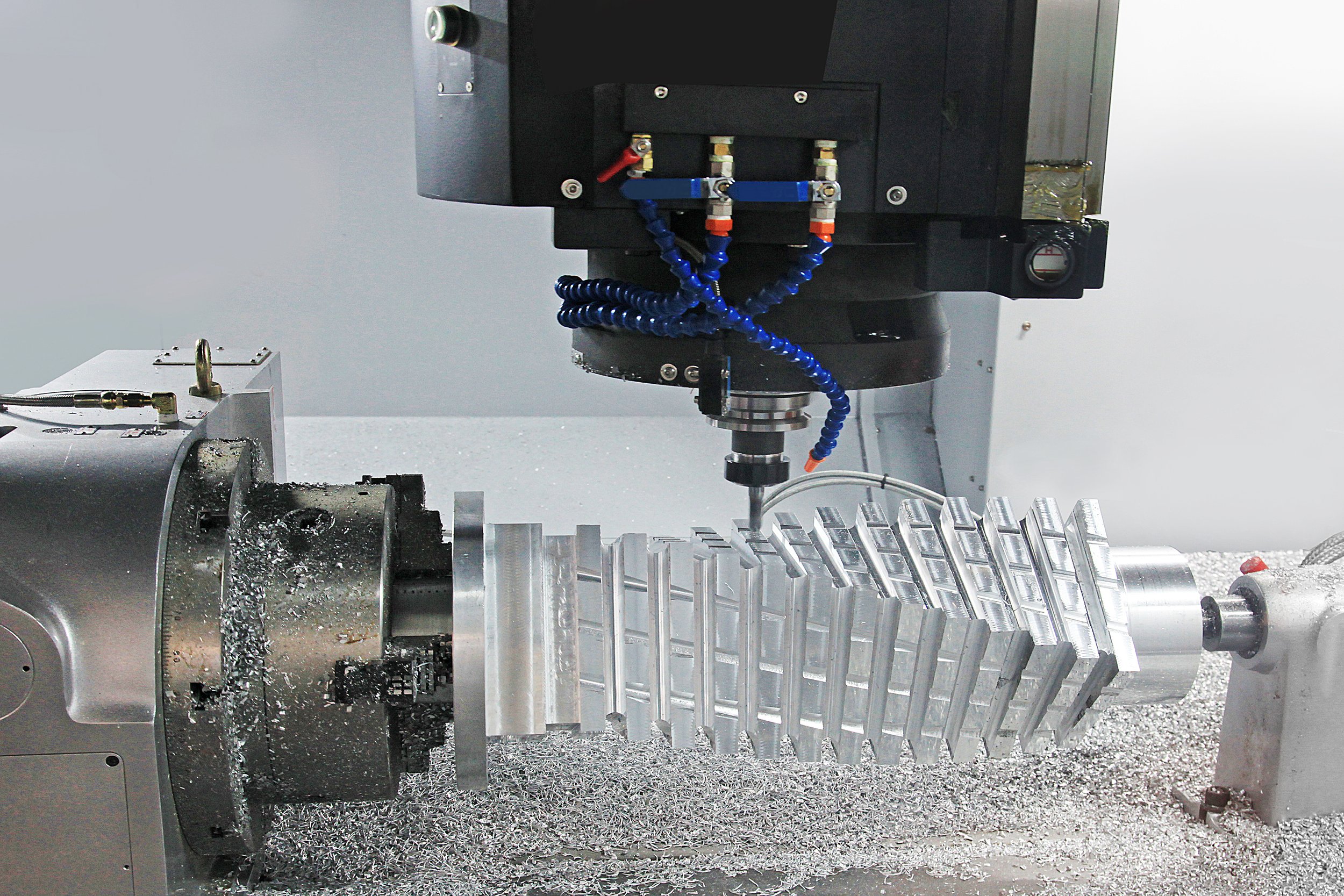

Cast iron being scraped

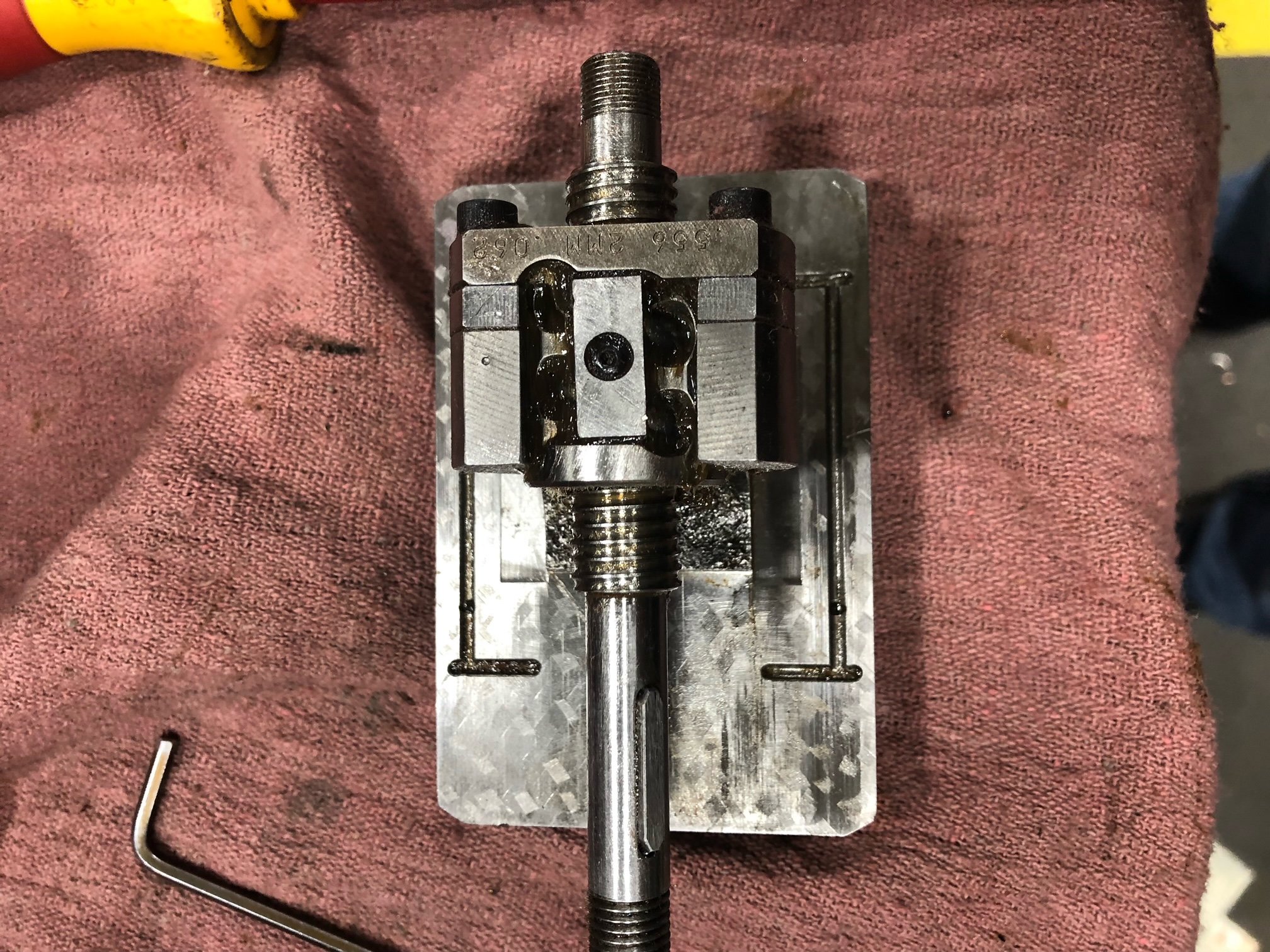

Small tool being scraped

Small tool being scraped

Finished tool

Past and Present Customers